Why U.S. Manufacturing is Shifting from China to Mexico?

Why U.S. Manufacturing is Shifting from China to Mexico?

In recent years, the global manufacturing industry has witnessed a profound transformation. Once dominated by China due to its low labor costs and large production capacity, U.S. companies are increasingly reevaluating their supply chain strategies. A growing number of manufacturers are shifting production from China to Mexico—a phenomenon driven by a combination of economic, geopolitical, and logistical factors. This trend, often referred to as “nearshoring,” is reshaping the manufacturing landscape, offering both challenges and opportunities for American businesses.

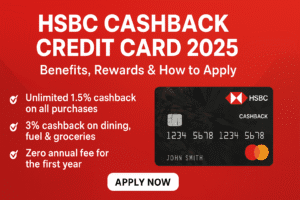

HSBC Cashback Credit Card 2025 – Benefits, Rewards & How to Apply?

Historical Context: Why China Became the Manufacturing Hub

China’s rise as the world’s manufacturing powerhouse began in the late 20th century. With policies encouraging foreign investment, a massive labor force, and inexpensive production costs, China became the go-to destination for U.S. companies seeking to maximize profits. Over decades, U.S. manufacturers outsourced electronics, apparel, automotive parts, and consumer goods to Chinese factories.

However, reliance on China also came with significant vulnerabilities. Trade tensions, intellectual property concerns, rising labor costs, and supply chain disruptions—exacerbated by the COVID-19 pandemic—highlighted the risks of overdependence on a single country for global manufacturing.

Economic Factors Driving the Shift

Several economic pressures have accelerated the migration of manufacturing from China to Mexico:

- Rising Labor Costs in China: Wages in China have increased significantly over the past decade, narrowing the cost advantage that initially drew U.S. manufacturers.

- Volatile Global Supply Chains: Natural disasters, pandemics, and geopolitical tensions have disrupted supply chains in Asia, pushing companies to diversify production closer to home.

- Inflation and Shipping Costs: The cost of shipping containers from Asia to the U.S. surged during the pandemic, making domestic and nearshored production more attractive.

Impact on American Businesses and Consumers

The shift from China to Mexico carries multiple implications:

- Reduced Lead Times: Products reach American retailers faster, improving inventory management and customer satisfaction.

- Potential Cost Savings: Lower transportation costs and tariffs can offset slightly higher production costs compared to China.

- Economic Benefits for U.S.: Nearshoring can create jobs domestically by increasing demand for logistics, distribution, and supplier services linked to Mexican production.

However, challenges exist, such as navigating Mexican labor regulations, potential security concerns in certain regions, and the need to invest in infrastructure and technology to match China’s production scale.

Technology and Automation in Mexican Manufacturing

Automation and robotics are playing a key role in enhancing Mexico’s manufacturing capabilities. Companies can maintain high production volumes while mitigating the impact of rising labor costs. Smart factories equipped with automated assembly lines allow Mexico to compete effectively with China on both quality and efficiency.

Future Outlook for U.S.-Mexico Manufacturing

The nearshoring trend is likely to accelerate as companies seek resilience, cost-effectiveness, and faster delivery. Key predictions include:

- Growth in High-Tech Manufacturing: Beyond traditional sectors, electronics, renewable energy components, and medical devices are increasingly produced in Mexico.

- Investment in Workforce Development: Mexican labor skills will continue to improve as companies invest in training and education.

- Enhanced Infrastructure: Mexican ports, highways, and industrial parks will expand to meet rising demand from U.S. businesses.

Challenges and Risks

Despite its advantages, nearshoring is not without risks:

- Political and Security Risks: Certain regions in Mexico experience instability or crime, requiring careful site selection.

- Regulatory Compliance: Companies must navigate local labor laws, environmental regulations, and tax policies.

- Supply Chain Bottlenecks: While proximity helps, shortages of raw materials and components can still create delays.

Conclusion: Why U.S. Manufacturing is Shifting from China to Mexico?

The shift of U.S. manufacturing from China to Mexico reflects broader trends in globalization, risk management, and economic pragmatism. Nearshoring offers U.S. companies a chance to improve supply chain resilience, reduce costs, and respond more rapidly to consumer demand. While challenges remain, the strategic advantages of Mexico—geography, trade agreements, labor costs, and logistics—make it a compelling choice for companies seeking a stable and efficient manufacturing hub.

As global trade dynamics continue to evolve, the U.S.-Mexico manufacturing corridor is set to become a cornerstone of North American industrial strategy, reshaping not just production patterns but also the economic landscape for American businesses and consumers alike.

The Future of Stablecoins Under U.S. Regulation: What New Policies Mean for Crypto and the Economy

The Future of Stablecoins Under U.S. Regulation: What New Policies Mean for Crypto and the Economy